Production

En toute transparence, découvrez les images de notre chaîne de production.

Une production localisée en Europe

Nous favorisons les circuits courts au maximum afin de réduire notre empreinte carbone. Nos produits sont conçus et désignés en Suisse. Les fabriques spécialisées en lingerie étant inexistantes dans notre pays, celles-ci sont de ce fait confectionnées au Portugal.

Nous collaborons avec diverses entreprises valaisannes et/ou suisses de confiance et de qualité pour tout ce qui peut être fait chez nous (Packaging, pochettes, étiquettes, etc.).

.

01 /

Recherche et développement

La conception et le design des lingeries sont réalisés par nos soins. Nous commençons par mettre à plat toutes nos idées, puis nous nous mettons en quête des matériaux idéaux auprès de nos fournisseurs (tissus, dentelles, élastiques, ornements, etc.). Une fois les matières réunies, nous dessinons et schématisons la coupe/design du modèle sous forme de photomontage.

02 /

Bureau d’étude

Une modéliste spécialisée en Lingerie et Bain, installée dans le nord de la France, concrétise nos idées en générant des dessins techniques, plus connus sous le nom de patronages. Ces données servent ensuite de guide pratique à notre atelier de confection pour le montage des prototypes.

03 /

Atelier de confection

Notre façonnier est situé à Braga au Nord du Portugal. C’est là que vos lingeries prennent vie. Cet atelier possède un savoir-faire spécifique dans la lingerie-corseterie et emploie des couturières passionnées qui œuvrent au quotidien afin de vous offrir une lingerie de haute qualité.

Après des séries de tests et de prototypages les designs sont validés. Afin de pouvoir maintenir des prix accessibles tout en privilégiant une fabrication européenne, le temps minute de notre chaîne de production a été optimisé au maximum.

Une telle confection nécessite l’infrastructure d’une entreprise équipée et spécialisée dans la production en chaîne. C’est-à-dire des tables de coupe automatique, de la programmation mécanique, plus de 8 machines à façonner différentes, chacune d’entre elles étant spécifique à une étape.

04 /

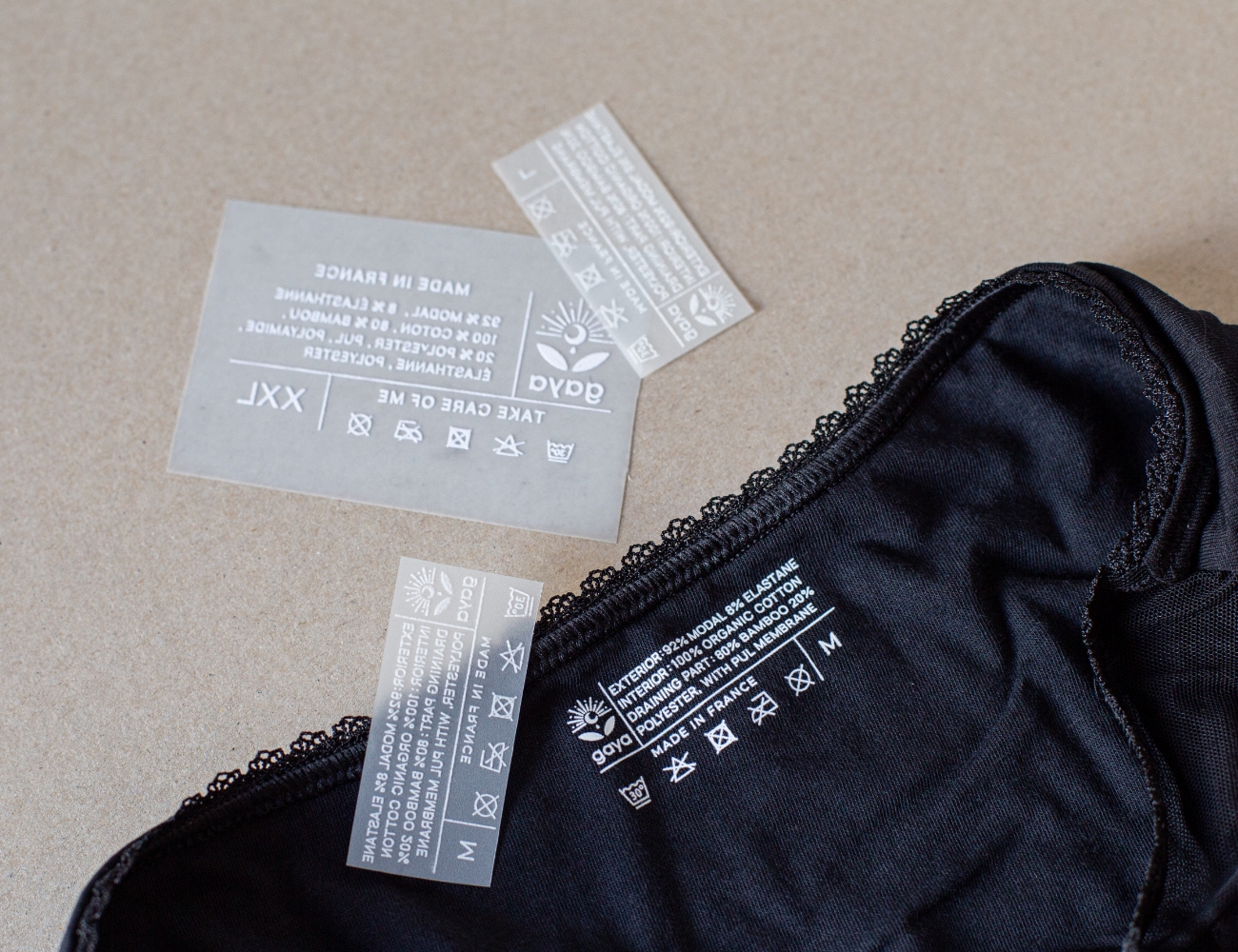

De la sérigraphie en lieu et place d’étiquettes généralement jetées

Lors de la phase de développement, notre attention s’est naturellement portée sur les étiquettes de composition et de lavage. Le fait que ces morceaux de tissus finissent la plupart du temps à la poubelle nous posait problème. Dans notre démarche de réduction des déchets, nous avons opté pour la sérigraphie qui est une technique d’impression spécifique par encrage sur tissu.

05 /

Logistique et manutention

Les lingeries sont réceptionnées dans nos locaux en Valais. Dès réception, chaque pièce est contrôlée et inspectée puis étiquetée. Nous empaquetons chacune de vos commandes avec tout le soin nécessaire pour vous offrir une prestation irréprochable.

En ce qui concerne les matières premières

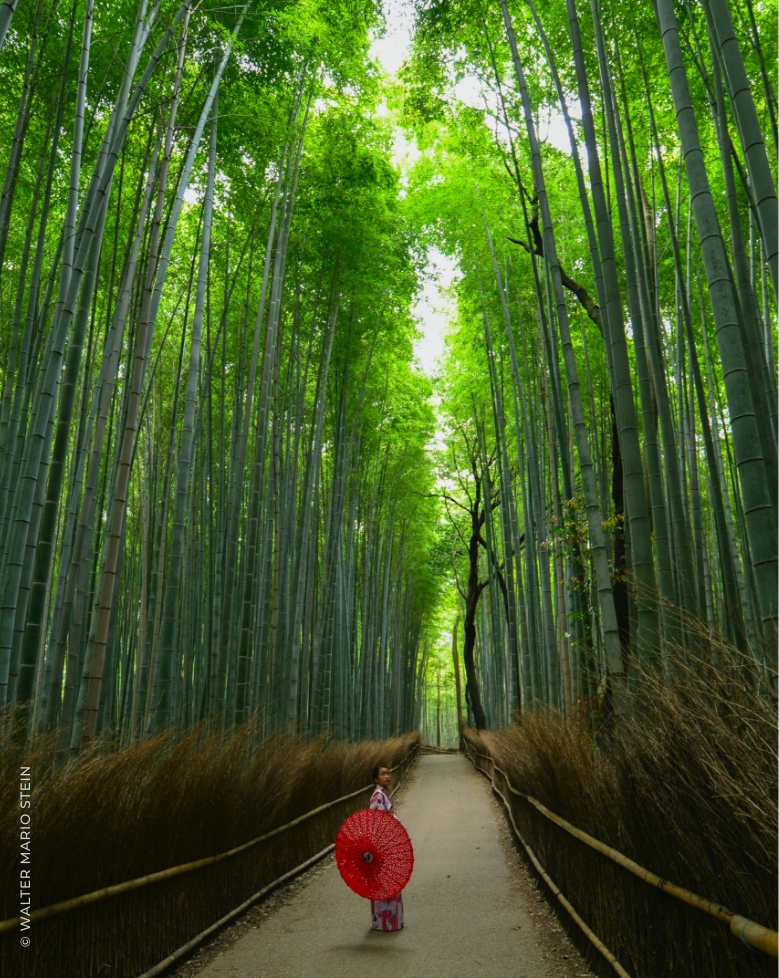

Il faut avoir conscience que la majorité des matières utilisées pour la fabrication textile sont cultivées en Asie.

Toutefois, nous collaborons avec des fournisseurs français et italiens nous proposant uniquement des matières de qualité, certifiées confectionnées dans le respect des normes européennes et environnementales strictes.

Nous sommes allées plusieurs fois à la rencontre de nos partenaires commerciaux afin de renforcer notre collaboration, créer des liens personnels et de confiance, ce qui fait partie intégrante de nos valeurs éthiques globales.

Modal, coton, bambou et PUL

C’est une entreprise familiale près de Lyon qui nous procure le coton et le modal. Pour le Bambou et le PUL, nous nous fournissons auprès d’une société située à proximité de Paris et spécialisée dans la vente de tissus éponges.

Elastiques

Les élastiques proviennent d’une fabrique proche de Lyon. Cette société est l’une des plus anciennes et des plus expérimentées d’Europe dans son domaine. Elle propose un très large choix d’élastiques pour la corseterie et les sous-vêtements.

Dentelle et résille

C’est un atelier familial proche de Milan qui produit la résille et le tulle. Cette société est réputée pour la qualité de ses toiles en microfibre, ainsi que ses tulles et ses dentelles dédiées à l’industrie de la lingerie.

Toutes nos matières sont certifiées OEKO-TEX. Ce label effectue de nombreux contrôles et garantit la non-nocivité des textiles pour la santé. OEKO-TEX, regroupant dix-huit instituts de recherche indépendants, a mis en place plusieurs labellisations aux cahiers des charges très stricts, qui s’adressent aux consommateurs qui souhaitent consommer de façon responsable bien sûr, mais aussi aux fabricants soucieux de maitriser toute leur chaîne de production.

Pochettes de transport upcyclées

Nous vous proposons également des pochettes UPCYCLÉES fabriquées à partir de bâches destinées à être jetées. Le UPCYCLING consiste à détourner des matières/objets afin d’en fabriquer d’autres. C’est revaloriser des produits usagés en leur donnant une nouvelle vie plus qualitative. Contrairement au recyclage, cette méthode ne nécessite pas la transformation de matières premières. C’est donc bien moins énergivore et plus écologique que le recyclage.

Chaque pochette est unique et cousue à la main en valais ! Les couleurs et les motifs varient selon les bâches récupérées.

Des packagings à faible impact environnemental

Emballage en papier d’herbe

Nos cartons d’emballage sont fabriqués en Allemagne à partir des déchets d’herbe. Une partie de la pulpe de pâte est remplacée par des fibres d’herbe. En plus des avantages de durabilité, le carton d’herbe obtient les meilleures notes en termes de faible empreinte environnementale, car la consommation d’énergie et d’eau dans la production de papier d’herbe est considérablement réduite.

Imprimerie de proximité

Pour tout ce qui est des étiquettes de vente, tracts et flyers, nous collaborons avec des entreprises de proximité en Valais (CH).

Papier recyclé / FSC

Nous utilisons du papier recyclé et/ou certifié FSC (Forest Stewardship Council). Ce label atteste que la fabrication est issue de forêts durables, que les arbres n’ont pas été abattus illégalement et ne sont pas issus de forêts d’utilisation non forestière.

Papier de soie, scotch, etc.

Nous collaborons avec une société suisse spécialisée dans l’emballage depuis 35 ans. C’est le premier fournisseur global certifié PEFC™ et FSC® et qui propose de nombreux emballages durables et écologiques.